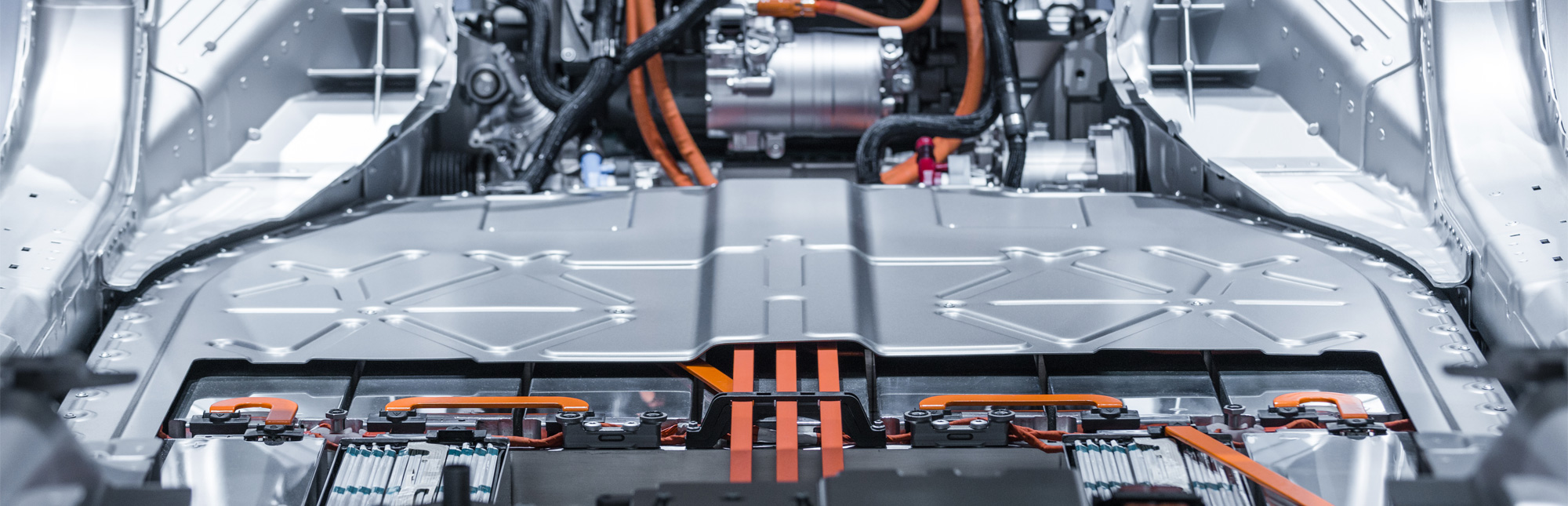

Parts cleaning in the e-mobility sector

Electromobility with battery or fuel cell drives and the development of innovative assistance systems are presenting parts cleaning with new and modified tasks. As a result, some cleaning applications now take place during the assembly process. One of the reasons for this is particles that are introduced by joining processes or purchased parts, for example, and can cause functional problems (e.g. short circuit). It is essential that particulate and non-volatile residues are removed from the ultra-thin materials of cathodes and anodes for bipolar plates. In addition, the trend towards adhesive bonding also calls for higher thin-film and particulate cleanliness of the bonding surfaces. Likewise, new lightweight, material and manufacturing solutions require adapted cleaning processes. This is also the case for components in safety systems, such as steering, brakes and ABS. For these tasks, Ecoclean develops and manufactures cleaning solutions that are optimally adapted to the task at hand. They not only ensure the required particulate and thin-film cleanliness but also maximum flexibility and cost-effectiveness.

Cleaning technologies for the e-mobility sector

Ecoclean is a full-range supplier of future-oriented, globally available solutions for industrial parts cleaning, aqueous surface treatment and customized automation. Adapted to the specific requirements and applications of vehicle manufacturers and suppliers (e.g. production process, type of contamination, cleanliness specifications, throughput rates, cycle times), a range of wet and dry cleaning processes are available, also for combined use in a single system. To clean parts efficiently, such as those for gear, brake and steering systems, our extensive portfolio includes water-based and environmentally compatible solvent-based cleaning machines. For example, with our surface treatment solutions, brake discs can be activated prior to coating to prevent corrosion and reduce fine dust emissions just as effectively and efficiently as weld seams on chassis parts can be cleaned.

Comprehensive expertise in parts cleaning for the e-mobility sector

To solve the highly varied tasks in the automotive and supplier industry in a requirement-oriented, sustainable and efficient way, comprehensive technological expertise is indispensable. However, application know-how is also called for. Thanks to our many years of experience, our early involvement in e-mobility and numerous successfully completed projects for OEMs and suppliers around the globe, we have both. This, in conjunction with our fully equipped Technology Centres, enables us to carry out cleaning tests for the e-mobility sector on original-soiled parts under near-production conditions in order to solve any cleaning task. Based on the respective material, component geometry, type of contamination, cleanliness and throughput requirements, we develop and automate flexible cleaning solutions that are both technically and economically optimized.