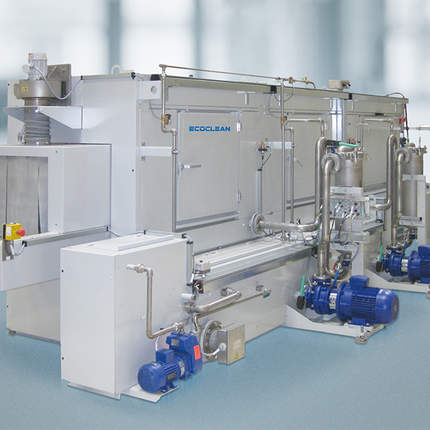

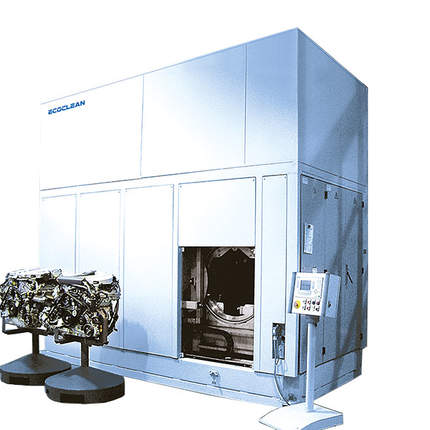

- Aqueous cleaning systems, e.g. flexible robot cells, transfer systems, in-line spraying systems, multi-chamber immersion cleaning systems, chamber systems

- Aqueous medium and high-pressure deburring systems (300 to 3,000 bars)

- Solvent-based cleaning systems as single or double chamber systems

- Aqueous or solvent-based cleaning coupled with plasma cleaning

- Solvent-based high-pressure cleaning (10 to 16 bars)

- Flexible process technologies, e.g. spraying, dipping, pressure flooding, injection flood washing, ultrasonic cleaning - also with different frequencies, pulsating pressure change cleaning (PPC)

- Flexibility in part agitation, e.g. turning, swivelling, oscillating

- Vacuum drying after solvent or aqueous cleaning, hot air drying coupled with vacuum drying (aqueous)

- Media reconditioning adapted to the respective cleaning technology, process, type of contamination and throughput, e.g. distillation, vacuum evaporator, ultrafiltration, deionized water plant, reverse osmosis, desalination solution

- Dry cleaning, e.g. plasma, laser, CO2, air, saturated water vapour

- Surface processing, e.g. pulsating high-pressure water jet

- Partial and full automation including transport of parts with roller conveyors, robots or loading gantries