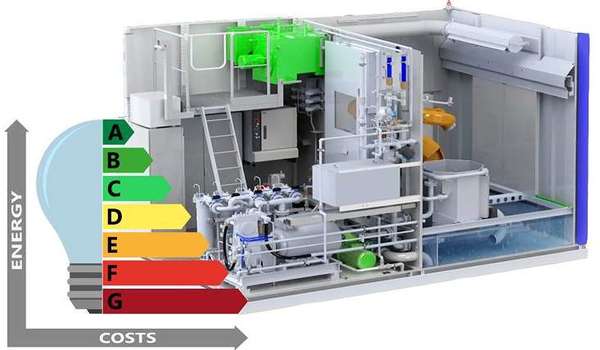

Mission Energy Efficiency in Component Cleaning

A key factor in reducing unit costs is the use of energy-saving potentials as identified during the production stage and also in industrial parts cleaning.

The Energy Optimization Service (or Energy Efficiency Service) offered by Ecoclean identifies potential savings for your industrial cleaning systems that, once implemented, mean a great improvement of the energy balance in the industrial cleaning technology. Especially for EcoCflex Classic systems, an extensive upgrade package is available including:

- Verification of power consumption with full and partial load production, in standby mode, etc.

- Verification of power consumption of individual units of the cleaning system (e.g. high-pressure pump, booster pump and blowers)

- Analysis of the whole installation, the workflow and the manufacturing process

- Inspection of machine heating and cooling systems and the machine insulation

These demand-based control of equipment modules yields major savings of usually:

- 30% less water consumption

- 30% less detergent

- 30% less electric power

- 30% less CO2

or more, depending on equipment configuration and processing times.

In addition, we help our customers to optimize other major energy consumers such as central coolant filtration systems.

Ecoclean's own Dynamic Flow Controller reduces the energy consumption wherever fluids have to be made available in non-uniform quantities.

Depending on the system configuration in place, high energy savings are possible up to:

- 45% less electric power

- 45% less CO2